|

The

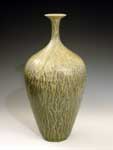

loading process can take quite a while. The wadding an

placement of each pot is critical to their eventual

outcome. When the kiln is stacked, and the door bricks

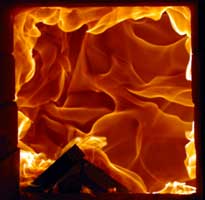

placed, we are ready to fire. We'll slowly take the kiln

up to cone 10 over the next 24 hours, starting out only

stoking the front stokebox, and eventually moving back to

put wood in the side stokeholes as the color and heat of

the front moves back through the stack. |

|

|

Once above

cone 10, we'll start cycles of reduction and oxidation for

the next 2 1/2 to 3 days, 24 hours a day, until cone 13 is

over in the front, and at least 10 is over all the way

back and through the kiln. In the large anagama, we'll

burn through a good 5 cords of wood in a firing. After

firing, we cool the kiln for a week. This are some of the

longest weeks of my life.. Opening a wood kiln firing is

like opening a treasure chest. There are so many

surprises. It's hard work, but the results are worth it. |

|

Some of my favorite wood fire slip &

glaze recipes

| Old

Black Magic Tenmoku |

Tony's

Blaze Slip |

Thorbjorn

Bronze Slip |

Pumice

Jade Celadon |

7.2

- Om4 Ball Clay

58.7 - Custer Feldspar

21.7 - Flint (silica)

12.4 - Whiting

1 - Tin Oxide

7.7 - Iron Oxide |

41

- Nepheline Syenite

41 - Calcined alumina

12.5 - Epk

5.5 - Bentonite

nice bright orange slip use thin

|

27.7

- Black copper oxide

45.46 - Manganese dioxide

18.18 - Epk

9.09 - Om4 ball clay

Apply to bisque, can run

|

80

- Pumice

20 - Wollastonite

2 - Bentonite

Stir well!

|

|